A new UV LED flexo press with central drum designed with 4.0 criteria, which does not generate ozone, consumes (little) clean energy, uses “food-grade” inks and adopts a low-temperature drying system, has been created to meet sustainability requirements.

The challenge was launched by the Treviso-based converter Termoplast Nord, which called upon its technological partners: to create a new type of flexo press with criteria of environmental and economic sustainability, which would produce high-quality, safe and green printed packages. The historic supplier Koenig & Bauer Flexotecnica, together with G Technologies Group for drying systems and Sun Chemical Group for inks, took up the challenge. By pooling their expertise, the four companies have created, tested and produced a new UV LED flexo press with a central drum that is of an original design and prints without emitting VOCs into the atmosphere, thanks to the use of special inks and coatings and new-generation UV LED lamps. The choice of energy supplier, which guarantees production without the use of hydrocarbons, is also consistent.

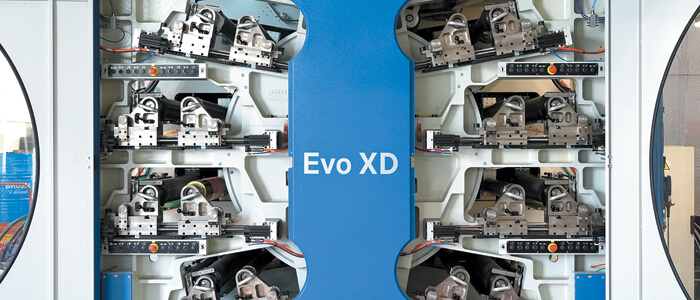

The new Evo XD

For Termoplast, Koenig & Bauer Flexotecnica has created a new 8-color central drum press Evo XD series, with a printing width of 1270mm (up to 1070mm for print format) using UV LED lamps: a technology that consumes less energy than traditional UV lamps and is also much more ecological as it does not produce ozone. The printing group of the Evo XD has been revised to include two new elements: these lamps and an inking group (doctor blade and pumps) modified to be able to handle the UV LED ink, which is known to have different characteristics and viscosity from solvent or water-based inks.

The drying system supplied by G Technologies (Giardina Graphic) develops a power of 40 W/cm2, one of the highest of its kind, and includes a cooling system that guarantees a very low temperature on the substrate. This enables superior printing results on heat-sensitive plastics such as PP, PE, PET, BOPP and others, and solves register and machine degradation issues.

In addition, the 4.0 design makes it possible to remotely control the system, integrate data into the company network, continuously monitor consumption, and store and select recipes.

Inks For the Termoplast project

Nord Sun Chemical has developed a series of Flexo UV LED inks suitable for this type of machine, i.e. formulated to be reactive to the UVA radiation emitted by UV LED lamps. Superior from a performance point of view, thanks to the greater penetration of radiation, they are perfectly suitable for printing food packaging. For this purpose Sun Chemical offers specific photoinitiators, oligomers and monomers for UV LED inks, characterized by high purity standards and extremely low migration levels.