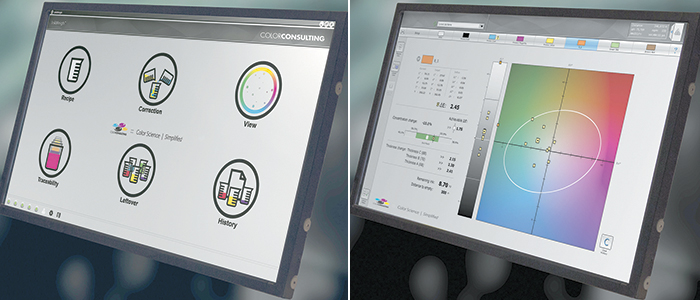

ColorTrack by ColorConsulting: production optimization and simultaneous communication between plants and an effective color workflow, for an unparalleled return on investment. Here are the figures.

At ColorConsulting, our solutions have helped many companies achieve their goals – both economic and in terms of quality – with very significant documented benefits. We detect them during periodic visits to our clients but unfortunately, we are not usually allowed to disclose them. Today, thanks to the cooperation of an open-minded entrepreneur, we can anonymously report the results achieved in his company, testifying with numerical data the impact of ColorTrack and InkWeigh solutions within a real workflow.

Manage inks in half the time

These solutions are typically installed in two key departments of the company: the color kitchen and the pressroom. Their impact then involves ink preparation time, returns management, makeready time and materials saved. Prior to the introduction of ColorTrack and InkWeigh, daily ink management operations required an average of 35 hours per day, with six operators involved across three shifts. With implementation complete, these times have dropped to 15 hours/day. For example, ink formulation used to take around 3 hours a day, but now takes an average of 90 minutes. This was possible because of the speed and accuracy in imitating new colors and the database of recipes associated with recurring jobs that do not have to be created again.

Valuing returns; reducing start-ups

Further benefits are derived from processing returns, with an innovative solution that combines mathematical calculation with the colorimetric method, allowing recoveries to be used as an alternative to new inks. The savings on inks and, no less important, the reduction and organization of warehouse storage, have had very positive implications in terms of costs/benefits. And that’s not all: the start-up times of the three flexo presses have dropped from 12 to 7 hours a day and the new workflow adopted reduces the number of corrections, optimizing production. This is in spite of the fact that semi-automatic correction operations take longer than “eye” correction.

Changing habits is good for productivity

These changes have generated several benefits. Among these are an increase in machine productivity and a saving on the media used during startup, which have gone from 1200 to 800 m per day on average. This is what our customer says: “The most complex aspect was changing work habits that had been ingrained over time, even though they were obsolete. Once this initial hurdle was overcome, we could see that the objectives we had set ourselves were fully achieved. In fact, to be honest, they went well beyond expectations”.