A new high performance laminator, 5 systems sold all over the world, new agents for Europe, Asia and the Middle East. During the open house at the end of May, in conjunction with Print4All, Remac presented the new solventless Mizar, cashing in on successes and contracts.

On the technical level, the heart of the event was the lamination tests with barrier materials and adhesives developed by HB Fuller for this type of laminate, conducted live on the new Mizar solventless laminator. But there was much more at stake. At its headquarters in Piacenza, during the open house organized at the end of May, while Print4All was held at Fiera Milano Rho, Remac Converting Srl also presented a complete offer of complementary machines and equipment, which covers all users’ needs, together with the experience and its technical team, and an ambitious internationalization program that has the company rise to achieve new goals. The Piacenza based company is in fact moving with increasing success on the global scenario, so much so that during the same open house it clinched sales contracts for 5 laminators, two of which destined to the new markets of Thailand and Syria. Hence the event closed with an extremely positive balance both in economic terms and in terms of visibility and future prospects, paving the way for new initiatives. The open house was in fact also an opportunity to establish new partnerships with agents operating in Asia and the Middle East, and to strengthen the Remac sales network in Europe.

Solutions on show

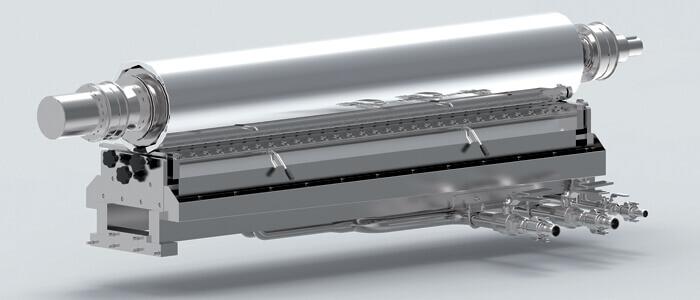

The visitors to the open house were able to evaluate various types of laminates done on the Mizar, dialoguing with the team of consultants formed by Remac technicians and adhesive experts. They were also able to view the other solventless laminators produced by the company – from the entry level Micra to the brand new solvent-solventless combined Multi DC – and their complete range of mixers: the solventless Newmix and Newmix Evo, the solventbase Multimix and the latest single-component adhesive dispenser Monomix. The solventless Mizar, for small and large productions, thanks to the special belt tensioning control systems, enables all types of materials to be used. The particular three-column configuration, extremely compact, allows easy and safe access to vital areas of the production cycle. In addition, the machine is supplied with full optionals, including standard mixer, automatic washing of spreading calenders, integral transfer roller, three-roller coupling system, shaftless system with increased supports, galvanized steel sides, and pneumatic opening of the doctoring calender to facilitate cleaning operations. The painstaking design – to be moved the machine does not require disassembly – minimizes installation and start-up times.