During last Flexo Day of Bologna, Inciflex Srl’s prepress service illustrated the outcome of the experiment carried out to obtain unprecedented levels of quality in the flexographic printing of all the critical elements of a printed matter. Here is a summary of the conference, from the pen of flexo production manager Loreto Simoncelli.

In October 2018, Inciflex Srl (Fisciano, SA) started an important experimentation, with the express purpose of equaling and – why not – surpassing the “gravure quality” in highlight artwork with zero screening percentages for flexography. A goal sought after in previous years by fielding Samba stochastic dispersion screens, without achieving the hoped-for results due to too many unknown quantities that needed checking in order to attain the desired outcome. But the drive for innovation made by Enzo Consalvo, owner and sole director of the only Italian service that covers all gravure, flexo and corrugated cardboard technologies, stands as an indispensable linchpin in the company culture and an “obsession” that involves all components and professional figures working there. Indeed the work has continued and today it has truly reached a new goal. Beyond all forecasts and expectations.

The start-up? An ambitious goal

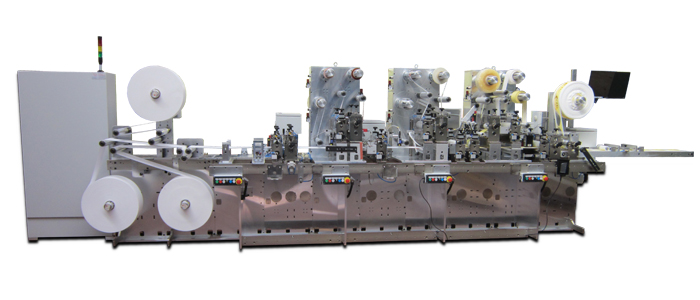

The project started from a wide-ranging experimentation, which examined different screening technologies and an impressive number of digital plates. A great deal of work that tested the Inciflex development team to the full with the fast rhythms involved. We carried out the first monochromatic tests that were proposed to us, to carry out the calibrations necessary for the development of the processes, with different printing companies and on different supports – PP, paper, cardboard, adhesives – embracing the widest possible spectrum.

The natural transition from monochromatic to four-color tests gave further answers in the technological comparison underway. In spring 2019 the results of this first phase of the experimentation were shared in a meeting that redefined the development guidelines. The comparison highlighted the strengths of UltraLed, a mix of technologies developed by the Inci-Flex R&D, which involves the use of sophisticated screens in combination with engraving algorithms developed ad hoc, and photopolymers with specific characteristics able to sublimate the tonal passages and the superimpositions of the chromatic inks, absolutely safeguarding the highlights of all the artwork tested.

From the considerations that emerged during the encounter, we continued with further tests, again shared among the participants, which allowed us to more clearly define the limits and strengths of the technologies under comparison. Several users and partners of Inci-Flex also took part in this long preparatory phase, making their professionalism and their companies available to carry out the necessary printing tests, even in prohibitive climatic conditions, with print start-ups carried out at extreme and very different temperatures and humidity covering all the four seasons.

The resources fielded

Overall, Inciflex has committed more than 1.5 million square centimeters of material to this project: an enormity, if we want to translate it in terms of individual printing forms. And this incredible amount of tests have been repeatedly printed, verified, measured and evaluated with extreme attention. Translated in terms of hours, it was a very onerous commitment, with meetings at various levels, comparisons with printers in turn committed to measuring and weighing the print outcomes, and expressing their relative evaluations. Furthermore, to further expand the experimental base to technologies/polymers on the market, with the best possible support, we made use of external collaborations, obtaining tests engraved in the USA and by other partners operating on the Italian market.

UltraLed wins the day

The comparison between the two systems finally rewarded Inciflex’s UltraLed technology which, in an incontrovertible way and according to the unanimous opinion of all those involved in the project, was judged superior. Passing from the experimental to the productive phase, the first printing forms made with this technology have given surprising results on different forms, with insignificant print minimums and zero highlights without obvious signs, extremely detailed tonal passages and perfect ink-on-ink overlays with considerable depth. UltraLed technology can be easily interpreted by all those who work with aniloxes with flow rates ranging from 3, 3.5, 4 to 4 grams per square meter, with preferably high linescreening (460/480/500) and a natural propensity for perfection. Yes, because the urge for perfection is also a distinguishing feature in production. And because UltraLed is a technology that is easy to interpret but not for everyone: only the best are able to interpret it to perfection.

Conclusions? No: openings

And now Inciflex, true to its DNA, relaunches by turning to new ambitious goals, with clear ideas and new projects in the pipeline. Because, in the world of applied research, every new goal achieved in technological development marks a new level, a new standard, which becomes the new starting point for further qualitative achievements.

The working group

The R&D work carried out in Inciflex Srl to develop the new UltraLed screening technology involved a somewhat composite team of professional figures, led by the owner and administrator Enzo Consalvo and coordinated by the flexo production manager of the Fisciano (SA) headquarters Loreto Simoncelli, by the director of the operating unit of Trezzano (MI) Giovanni Rossetti, by the head of engraving Valentino Mosca, by the expert in photopolymer calibration Mario D’Agostino and by the profile and color management head Sergio Celano. Christian Morelli and the full team of graphic designers, who contributed to the preparation of the tests and all the artwork developed to test the strengths and weaknesses, limits and potential regarding aniloxes, inks, printing machines, as well as variables related to the strong climatic influences of the various seasons, were also directly involved in offering their contribution.