Sustainability or ESG (Environment, Social, Governance) issues are at the center of attention of companies and markets, stimulating companies in the printing world to direct their investments to adapt operations and offerings to new requirements. Rossini SpA, has done so as the innovator that it is, revising the very paradigm of cylinder for rotogravure printing and coming up with an alternative that solves the current problems of environmental compatibility of the traditional product at the root, Introducing a production system that uses no water, with almost no impact on air and soil contamination.

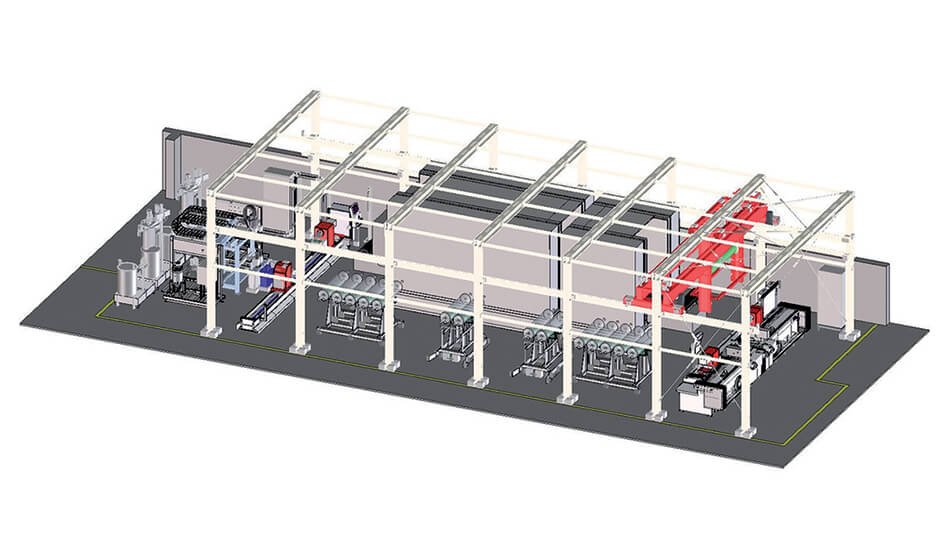

The outcome of this effort is Ecograv System: a complete system for the production of roto printing cylinders from environmentally friendly synthetic polymer, which completely eliminates copper and chromium and the health and environmental concerns these materials can pose. Excellent tests under real conditions Rossini’s new system is now tested and industrialized, and Ecograv cylinders are already being used with satisfaction, under real production conditions, by major rotogravure printers. An entire Ecograv line, complete with all the elements for the production of the new cylinders, is installed at the Rossini Equipment plant in Ubodo (VA), available for visits and demos and will be presented on video during the “K” fair. The project has attracted the interest of top gravure printers, who are booking a visit to the Rossini booth.