A global technology leader headquartered in Italy, IM Group is the parent of: Inkmaker, Rexson, Vale-tech, Swesa, Teko, Tecnopails and IEC+. IM Group combines the strength of each of its brands to offer integrated solutions across two specific business units: the Dispensing and Tinting unit and the Filling, Mixing and Grinding Unit.

In particular, we focalised our attention on Pesa by Inkmaker, the manual-blending system for offset, flexo and gravure inks. Pesa increases accuracy with a self-calibrating software and precision scale, and simplifies production and traceability with barcode/QR-code Systems.

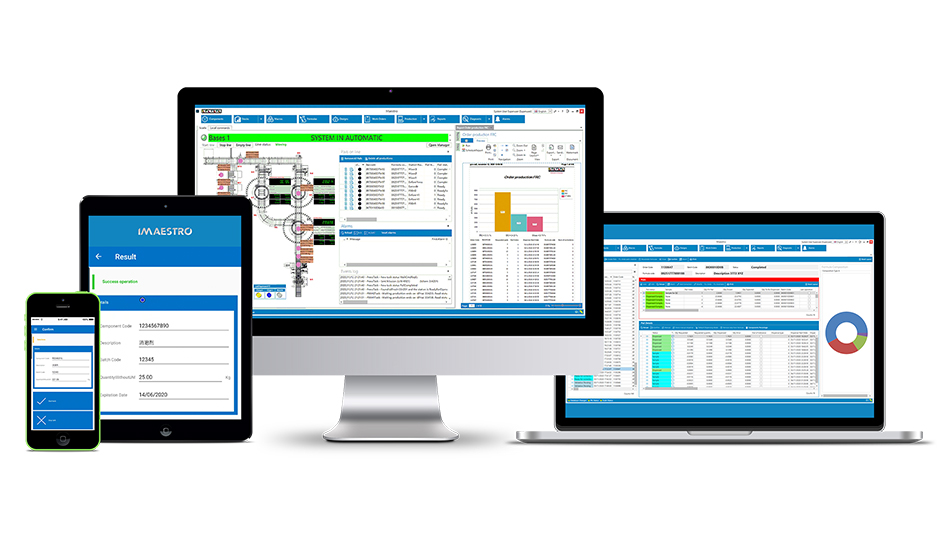

Pesa allows to drastically reduce ink formulation times, allowing printers to create their own formula, test it, make any changes and subsequently send it to IM GROUP’s in-house designed software, “IMAESTRO”, in just a few minutes. Furthermore, tests can be carried out on small product quantities – approximately 100 grams – and move on to much higher quantities only in the production phase. That is, a notable increase in the efficiency of the process, both in terms of time and resources. This also helps the operator, who no longer requires a high level of personal specialization, but is guided step by step in the formulation process.

We had the opportunity to talk with Lau Kar Seng, general manager of Inkmaker Shanghai, about the Asian market.

“We have many clients in the Asian market, and many installed machines. In China there is now a trend moving towards the creation of many special colours, and automated systems are on the growth. We are able to modify our software to meet this new trend, offering control over the colorimetric values of the formula. We match these values with the tagged colour and make the necessary adjustments before we use a tagged colour to search a certain ink. Now we are doing the process the other way round, using the ink to search for the desired colour. All in, this is a more efficient way. In our facility in Shanghai there is a team of 18 people dedicated to do colorimetric training for clients; to use a dispenser, to maintain a dispenser, to use the colour database and so on. Our focus is shifting from the simple selling of a product to the selling of a product PLUS all the training and the post-selling service attached to it. It’s a more efficient approach and we are seeing many printers in China appreciate this kind of attention to detail.”