Long-established Nuova Erreplast has installed a 10-color BOBST EXPERT CI flexo press as the Italian flexible packaging specialist looks to expand production capacity and increase productivity. This is a new partnership that reaffirms the market’s trust in BOBST as an innovation and technology pioneer.

The flexible packaging market is a fast-evolving sector with growth predicted to continue at a rate of 3.3% each year to 2024, according to the latest report from Smithers. New packaging formats and innovation in substrates dominate, with a gradual replacement of rigid packs taking place in favour of flexible packaging types. Reduction in material use, transportation costs and energy used throughout the supply chain are compelling benefits.

Nuova Erreplast is one the fastest growing converters of flexible packaging in southern Italy, with a more than ten-fold increase in turnover over the past decade. To continue this growth and enable further innovation, the company has now chosen to work with BOBST and invest in the best-in-class top-of-the-range EXPERT CI flexo press to support its vision of the future.

“After carefully considering our position and analysing market demands, we decided to partner with BOBST for our next major investment in printing technology”, said Nuova Erreplast’s CEO Domenico Raccioppoli. He added: “BOBST is well-known for its market-leading flexo technology and for reliability, and the EXPERT CI press has all the features in terms of productivity and process innovation that we need to meet upcoming challenges and enable us to expand”.

Easy manufacturing with sustainability benefits

The 10-color BOBST EXPERT CI press at Nuova Erreplast can process 1300 mm wide webs and offers a top production speed of 600 m/min. BOBST’s triLOCK bearing technology on the print decks enables faster operation and eliminates manual locking. This avoids process inconsistency and ensures perfect positioning for highest quality print and less waste.

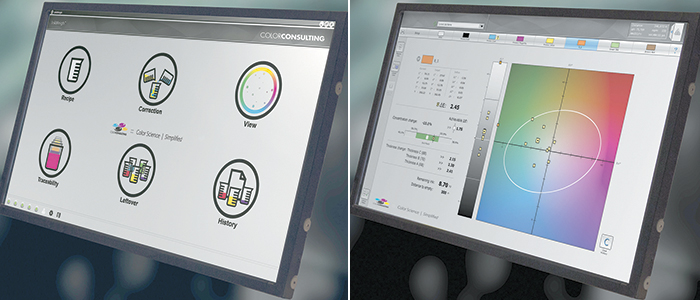

Among the host of other innovative features, the press is also fitted with smartFLO inking and doctor blade chamber system for predictable and controlled results and smartGPS offline fully automatic registration and impression setting for minimum start up waste. The high-efficiency Full Surface Matrix (FSM) inter-color dryer uses lower temperatures thereby saving on energy and preventing issues with substrate stretching. The press is also fully prepared for oneECG seven-color Extended Color Gamut printing.

The very high degree of automation is complemented by the EXPERT CI’s connectivity features, which mean that the Nuova Erreplast team can access production data remotely with ease. It also enables predictive maintenance so parts can be replaced before they fail to avoid costly processing errors and downtime.

Leading the way in flexible packaging

Located just north of Naples, Italy, Nuova Erreplast was founded in 1980 by Crescenzo Raccioppoli and is still family-owned, with the position of CEO taken over by family member Domenico Raccioppoli, who has been leading the company since 2004.

It is part of Raccioppoli Group and today operates from a new 55,000 square metre site, which was opened in 2018 and includes a fully automated 6,500 pallet warehouse. The BOBST EXPERT CI has joined a fleet of existing flexo presses in the converting department. The facility also includes extrusion for in-house production of a wide range of filmic-based packaging applications, and there is a very high degree of focus on automation, efficiency and sustainability.

There has been significant expansion particularly into the food sector with packaging produced for dairy, meat and frozen goods, pasta, confectionery, snacks and bakery items – a great success for Domenico and his team. The company also supplies many types of flexible packaging solutions to customers in the industrial, pharmaceutical and fashion industries, and some 35% of all production is exported, most notably to North America.

Recently Nuova Erreplast has also made a significant investment in a new manufacturing line for making medical, aseptic and antibacterial packaging, and during the worldwide COVID-19 pandemic, the company has initiated mass production of medical masks.

Forward together in innovation

Faster delivery, shorter run lengths and more environmentally friendly substrates are some of the many demands faced by packaging suppliers in today’s market. Full cooperation and trust between converters and equipment manufacturers is needed to meet those challenges and develop the right solutions.

Mr Raccioppoli said: “You have to find the supplier that you believe will make your dreams come true. We have very specific goals in mind, both for ourselves and for our customers, and it is clear that BOBST can help us achieve those goals”.

“We are very excited and proud to welcome Nuova Erreplast as a new customer to BOBST, and we look forward to a long and fruitful cooperation as we together push the limits of flexo in Italy and beyond”, said Danilo Vaskovic, Sales Director, Bobst Bielefeld. “The EXPERT CI press will help Nuova Erreplast maximise productivity through more automation, faster changeovers, less waste and full connectivity, and it will also increase their sustainability targets. It is simply a winning combination.”

“At BOBST we work hand in hand with our customers to facilitate their growth and keep them at the forefront of the market”, Alberto Vaglio Laurin, Zone Business Director Italy, Bobst Italia concluded.