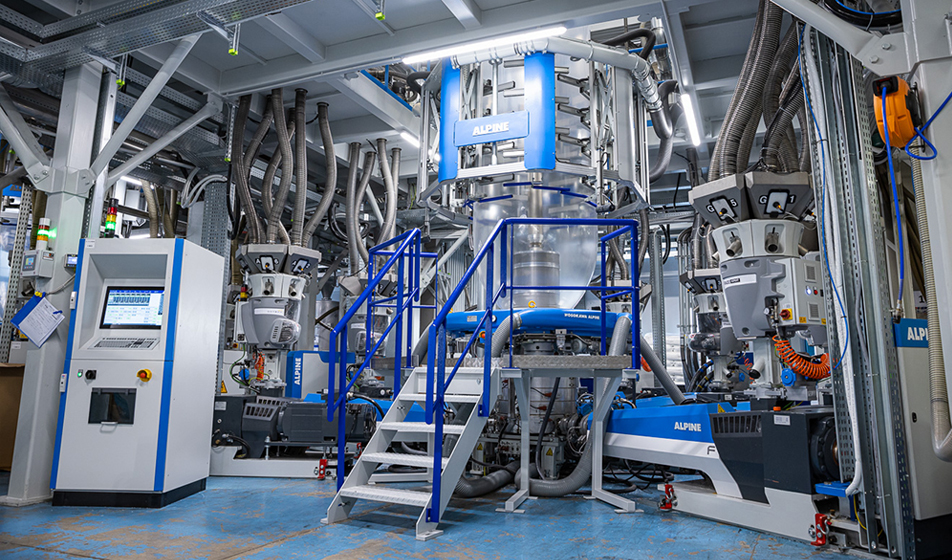

Italian packaging manufacturer ManuliTech has invested in a modern 7-layer blown film line with inline MDO from Hosokawa Alpine to produce laminating and laminate films with oxygen barrier in full PE design. In this way, the company intends to position itself early on as a solution provider for plastic packaging with a high recycling rate, thus opening up an important future market.

ManuliTech, based in Cambiago near Milan, produces multilayer blown films for customers primarily in the food and pharmaceutical industries. The rapid success of the young company confirms its good sense for current and future market needs: Already in 2018, production capacity was around 12,000 tonnes. In 2019, it could be increased to 15,000 tonnes. “ManuliTech has achieved a very high level of quality within a very short time,” explains Nicola Pirani, Alpine’s representative in Italy. The first Alpine line was installed at the site in northern Italy in 2020. It has contributed significantly to ManuliTech’s rapid success with the film quality produced. ManuliTech is now consistently continuing its strategy of quality leadership. This was followed last year by the construction and configuration of the new, flexible 7-layer high-performance line with inline MDO (Machine Direction Orientation) to meet the demand for full-PE films in Italy at an early stage. “The market for Full-PE barrier films is growing in Italy, but it is still difficult for end-customers to get these films in consistently good quality and sufficient quantity,” Pirani explains. This gap would now be closed by ManuliTech.

In accordance with the principle of the circular economy

Until now, in order to achieve the desired product properties, composites had to be produced from different materials that cannot be fully recycled. A much more environmentally friendly concept is full PE packaging solutions with films made from pure polyethylene composites. These can be fully recycled after their original use and reused without material loss in the circular economy for end products. Thus, sustainability and resource savings are combined. “We support this circular economy approach and offer our customers suitable solutions for it,” explains Alessandro Manuli, managing director at ManuliTech. MDO technology serves the increasing need for recyclable mono-packaging. “This is a long-needed development for the sustainability principle and a promising growth market for us.”

Precisely tailored line design and high film quality

“More than 100 MDOs made by us are in operation worldwide,” points out Stefan Sager, Operations Director in the Film Extrusion Division at Hosokawa Alpine, referring to the success of the last 25 years since the technology was introduced. Together with its customers, Hosokawa Alpine designs the particular MDO blown film line to fit the desired film production, tailored exactly to the customer’s needs. “That’s one secret to our success, the other is the quality of MDO film,” adds Sager. It is characterized by excellent processability, optimized flatness and no hanging edges. To achieve this, Alpine’s MDOs are equipped with three unique features: TRIO technology (Trim Reduction for Inline Orientation) for best flatness and roll cylindricity, flexible stretch gap adjustment to reduce neck-in, and unique vacuum technology for best flatness and excellent process stability.

Hosokawa Alpine MDO technology is based on monoaxial stretching of blown film. In this process, the film is drawn between two rolls which rotate at different speeds. Depending on the application, the film runs over eight to twelve rolls, two of which are stretching rolls. After heating to the optimum temperature, the film is brought to the desired ratio in the stretching phase. The stretching process reduces the film thickness while improving its optical and mechanical properties. These include, for example, barrier properties, transparency or processability. “This technology reduces the need for raw materials in a resource-saving way, while also increasing efficiency,” explains Sager. The stresses created during stretching are reduced in the subsequent annealing phase. Finally, the film cools down and compensates for the thermal shrinkage.

TRIO increases finishing quality

The TRIO system integrated into the line reduces neck-in by up to 50 percent. At the same time, the flatness of the film is optimised, and a uniform thickness profile is produced. “TRIO 2.0” is a further development of the system and is now on the market. It includes single-layer measurement of the stretched film after slitting and before the winding points. “This more precise detection of the film layers enables even better positioning of the thin sections for the stretching process,” emphasizes Sager. A smart control algorithm calculates an improved mapping of the influences from the MDO on the entire control loop from the measured values. The optimised recording and calculation of the target values for the thin sections makes the control in the inline MDO process more precise and thus increases the further processing quality.

Trend-setting technology for the production of monomaterial barrier films

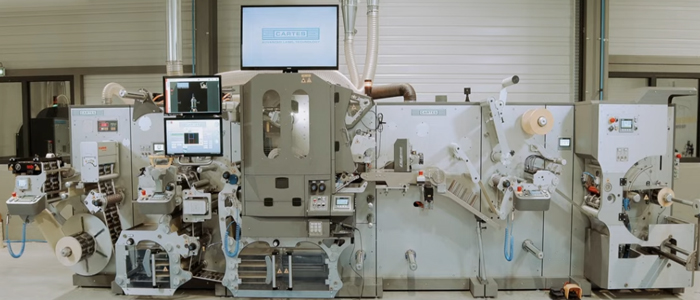

ManuliTech uses the new blown film line to produce monomaterial films from polyethylene. When an oxygen barrier is needed, ethylene vinyl alcohol plastic (EVOH) is used as abarrier layer. If the EVOH content of a film is less than 5 percent, it does not affect recyclability in the PE waste stream. “Alpine is not only a pioneer in MDO technology, but also a market leader. We are pleased that, together with this competent partner, we have been able to integrate a new, future-oriented component into our product range,” says Managing Director Manuli. Alpine Support is available to provide advice on all questions relating to blown film production. In this way, ManuliTech can offer customers high-quality solutions for a sustainable circular economy in plastic packaging and also permanently optimise the technology.