An HP Indigo 20000 operating at ACM Packaging (the second in Italy in the “high speed development” segment of flexible packaging) and the second digital for post print on HP PageWide C500 Press corrugated cardboard installed in Europe at LIC Packaging, Verolanuova, for the creation of food-compliant packaging with the use of water-based inks.

Common elements: the innovative verve of the two Italian converters, who paved the way for digital innovation in two segments of packaging – flexible and corrugated, in fact – where this technology offers great potential for development; and the commitment of the entire HP technical and marketing staff at the works of these two customers, which is not only supporting a “smooth” production of the machines and the adequate training of the personnel, but that is also aiding the strategists and creators of the two users in helping them discover the potential applications of a technology that is still largely underutilized and underexploited.

We saw them working together, supplier and converters, in the open houses that have followed in recent weeks: October 24 for customers and November 14 for the entire AMC package printing community, with the direct involvement of the creatives of the HUD Agency; November 14th and 15th at LIC Packaging, where HP organized an international event, with experts, operators and prospects from all over the world, on digital in food packaging and in particular involving corrugated packaging (insights coming shortly).

The large HP Indigo 20000 opens up to new markets

With over 160 units installed globally (a year ago there were 100), the HP Indigo 20000 allows you to print a wide range of polymer (even shrinkable) and cellulose based substrates with thicknesses up to 350 microns. It supports coils with a 76 cm web width, with reduced consumption and waste even on small runs. Its features in terms of versatility and performance are worthy of further study: for a machine description CLICK HERE. You’ll have to wait for the next issue of Converting for its role as a digital battering ram in the world of flexible packaging.

The HP PageWide C500 Press

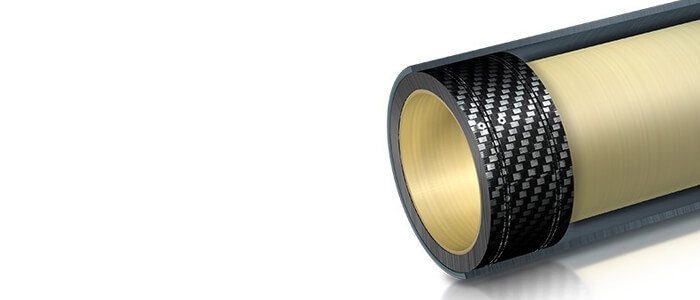

This machine prints a wide range of coated and non-coated media with an “offset quality”, with a mainstream productivity and full use in packaging (and lamination). PageWide C500 Press manages corrugated cartons with double wall thicknesses from F to BC. Unlike other digital printing systems that use piezoelectric inkjet technology with a resolution of 360 dpi or 600 dpi, the PageWide C500 Press adopts HP’s patented thermal ink jet, developed to ensure maximum print quality at the given speed of production. With a resolution of 1200 dpi and one million nozzles, the C500 printing system prints in the most demanding production environments, at 75 m/min at the highest print quality. The HP inkjet thermal technology is characterized by the high redundancy of the nozzles (up to 6 times), unattainable with piezoelectric ink jets. In addition, the HP PageWide C500 Press water-based inks allow printing on primary and secondary packaging for the food industry without the need for an additional barrier. This ensures compliance with the most stringent global food safety regulations, such as the Nestlé guidelines and the Swiss ink ordinance. The story of its adoption in LIC is on the way, with anticipations on the market analysis and the projects of the Brescia converter.