FAS SpA is a well-known baby diaper manufacturer, with an ambitious global development program supported by significant investments in logistics and production. But they still had a challenge to face… The history of the collaboration with Mitsubishi Materials Ryotec, the redesign of a critical component and the great benefits found in terms of quality and quantity of the output.

FAS SpA, in its Corato (BA) plant, produces diapers, women sanitary pads and panty liners. Its history began in 1982 and the business grew big in just a few years, until, in 1994, a real organizational process was implemented. Today the Apulian company employs about forty employees, with 30% of its production under the FAS brand and 70% for the private label market for large distribution big brands, pharmacies, parapharmacies and early childhood stores.

FAS is a certified company according to all standards that guarantee quality and safety of products worldwide, their compliance, the absence of foreign objects, the sustainability of production processes: all fundamental requirements to become certified suppliers on the international large-scale retail market. The results are for everyone to see: FAS has experienced an excellent growth in its activity on foreign markets, reaching the American continent after consolidating its presence in most of the European territory and in North Africa. Driven by the high quality of its products and the Made in Italy prestige, the international turnover has gone from 0 to about 20% in just a few years.

But the effort is not limited to production and processing: the company has recently obtained a certification that attests to its commitment in ethical and social responsibility with respect to customers, operators, suppliers, the environment.

Automatic lines and flexibility

The mission of FAS SpA is to provide customers with high quality products and services, working in partnership with its suppliers for the development and implementation of the most efficient environmentally and safety friendly technologies. Francesco and Mauro Squeo, Sole Administrator and Head of Management Control of the Apulian company, underline this: “We believe that dealing with hygiene products means dealing with the quality of everyday life. FAS wants to be recognized as a protagonist and an excellent alternative by its customers. Creating high quality products, investing in technology, offering employees continuous growth opportunities is the common goal. And we are deeply convinced of the value of people, the diversification of skills and professional development as tools for constant growth.”

The company entrusts production to four highly automated lines: in a few minutes the raw materials (cellulose, super absorbent fluff, non-woven fabric and packaging) are transformed into the finished product under the expert eye of the technicians who control the plant’s flows. A project for the near future is to implement further automatic processes, so that wares can be moved between departments without any direct human intervention.

An internal maintenance department is dedicated to periodic and systemic checks, in the belief that lines must always be kept at maximum efficiency. Thousands and thousands of packages are processed every day at a really fast pace and every mechanism must be precise and reliable.

Flexibility is the real strength at FAS, that is the ability to quickly switch from one format to a different one, thanks to reduced set-up times, careful production planning and, of course, excellent staff preparation. This flexibility has a positive impact on outbound logistics as well, allowing a wide range of types and formats to be managed, including those directed abroad. With a great advantage for the client, who is not forced to store large quantities of goods in their own warehouses: a feature that is particularly appreciated today, as well as being able to rely on a supplier that is always on hand.

The supplier as a partner

The Apulian company has always paid particular attention to the choice of flexible and qualified suppliers. “This determination gives us the possibility to optimize our processes,” the entrepreneurs declare. “We welcome every supplier, confident that continuous dialogue and collaboration can make our business grow: the supplier can bring to our attention technical solutions that we may not know of. Everything is aimed at improving our production and logistics chain.”

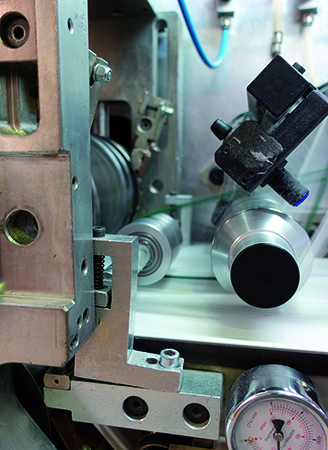

That’s precisely what happened with Mitsubishi Materials Ryotec, a well-known and renowned company in the tool manufacturing sector, a world leader in the development and production of wear-resistant components. The close collaboration between FAS and the Japanese manufacturer has led to the development of a component of great importance in one specific production line of the plant, the so-called “castle”. It is a mechanical unit in which two stator- and rotor cylinders operate, between which runs the pre-assembled strip of the absorbent material, intended to be cut according to the shape of the rotary blade pressing down on the lower steel cylinder.

This piece is very critical: the rotary cutting tool (Rotary Die Cutter as described in Mitsubishi’s catalog) is the heart of the line. Given the high working speed, the tolerance of the components in play must be absolutely under control: even a few microns can cause imperfect cuts, processing waste, tears in the line, up to the blocking of the line itself – in a word, damages to be absolutely avoided. In addition to the geometric dimensioning, another parameter to be carefully adjusted is the pressure between the rollers: if too low the cut will be imperfect, if too high the blade will quickly deteriorate, and so will the lower cylinder. When evaluating all critical issues involved, it should also be considered that each type of product (diapers, or sanitary pads with or without wings etc.) has some variations to it, even in the chemical composition of the components – a higher or lower cellulose density, weight of materials etc.

Optimize consumables, reduce costs

The blade inevitably wears out: “We needed a new blade – say the two entrepreneurs – and we wanted to address the problem of spare parts with a reasoned analysis, following the company’s logic that provides for a careful design of every aspect of the line. In our work, in fact, 70% of the product’s cost is to be attributed to the raw material, so it is mandatory for us to optimize all the phases of production, including the use of consumables, in order to reduce costs and eliminate waste. In this case, we needed as many tools as the possible formats, with longer lives.

The partnership with MMC Italia was the solution: the Italian branch of Mitsubishi Materials Ryotec studied the problem with our technicians, despite the uncertainties of the pandemic times. The worn-out unit was sent to Japan; there the lower roller (which works counter-blade) was modified and the new carbide-tipped knife was created. Completing the entire operation required the utmost attention, and to date the unit is installed and is working to our great satisfaction. From the first day we were able to obtain a perfect cut; and we are expecting a much longer knife life”

Technicians from FAS and Ryotec played a real team game to develop this solution. Particularly accurate was the adjustment of the cutting pressure, the value of which is responsible for the long life of the blade and the reliability of the process. On the other hand, MMC Italia is not new to partnerships like this one, actively contributing to always provide innovative responses to operators’ demands.

More precision and durability: out-of-the-ordinary performance with MMC Ryotec Rotary Die Cutter

MMC Ryotec provides a high quality, reliable cutting blade using a CAM simulation process and high-level grinding technology. Its applications are manifold: Diapers – Women sanitary pads – Band-aids – Batteries – Labels – Fuel Cells

MMC Ryotec provides a high quality, reliable cutting blade using a CAM simulation process and high-level grinding technology. Its applications are manifold: Diapers – Women sanitary pads – Band-aids – Batteries – Labels – Fuel Cells

The MMC Ryotec Rotary Die Cutter has been proven to offer precision, quality and robustness thanks to the combination of the tungsten carbide technology and the rigidity of the unit, paired with a precise production process and a detailed control system.

The combination of the wear-resistant tungsten carbide of the knife and, in this case, the impact-resistant steel of the counter knife, ensures a high quality cut while maintaining strength and longevity. At FAS the development of the application immediately gave excellent results, as demonstrated by the number of units of this type installed throughout Asia, which have been operating for years with significant durations.

FAS SpA is a leading company in the field of baby diapers as well as in the production of women sanitary pads and liners and in the marketing of other various personal hygiene products.The mission of FAS SpA is to provide customers with high quality products and services, working in partnership with its suppliers for the development and implementation of the most efficient environmentally and safety friendly technologies. Producing high quality Made in Italy products, investing in technology, respecting the environment, offering employees opportunities for continuous personal and group growth is the goal which all the company’s activities aim at. The fulcrum of the entire production is located in an area of about 3000 square meters, which houses 4 production lines: 2 baby diapers lines, 1 sanitary pads line and 1 for panty liners. The whole process is fully automated: in a few minutes the raw materials (cellulose, super absorbent fluff, non-woven fabric and packaging) are transformed into the finished and packaged product. Each production line has its own manager, while product quality monitoring is constantly carried out by qualified personnel.

Tel: +39 080 8728856

Email info@fas-spa.it

Website fas-spa.it

MMC RYOTEC Corporation (formerly known as OTE Kosan CO. Ltd.) was founded in 1958 as a company of the Mitsubishi Materials Corporation group (then Mitsubishi Metal Mining CO., Ltd.) from which, over time, it inherited some assets. These include the development and production departments of wear-resistant tools and rock tools which were then transferred from Mitsubishi Materials Corporation to Ryotec in 2000.Today MMC RYOTEC is recognized as a leader in the production of high quality hardmetal tools, not only in Japan but all over the world. Prominent products include hardmetal rollers for hot lamination in steel production, the die covering for lithium-ion batteries of electric vehicles, rock tools for the mining industry and hardmetal parts for various cutting tools.

MMC RYOTEC Corporation (formerly known as OTE Kosan CO. Ltd.) was founded in 1958 as a company of the Mitsubishi Materials Corporation group (then Mitsubishi Metal Mining CO., Ltd.) from which, over time, it inherited some assets. These include the development and production departments of wear-resistant tools and rock tools which were then transferred from Mitsubishi Materials Corporation to Ryotec in 2000.Today MMC RYOTEC is recognized as a leader in the production of high quality hardmetal tools, not only in Japan but all over the world. Prominent products include hardmetal rollers for hot lamination in steel production, the die covering for lithium-ion batteries of electric vehicles, rock tools for the mining industry and hardmetal parts for various cutting tools.

Tel: +39 360 1058852

Email luciano.garzia@mmc-italia.it

Website ryotec.co.jp/en/