Today’s rolling processes are evolving both in terms of the product to be applied and in terms of thicknesses and substrates. This entails a thorough overhaul of all process components. Simec Group, thanks to collaborations with leading operators in the sector (from machinery to adhesive manufacturers), as well as with large converting groups, has for some time now undertaken specific studies and tests on different plant components and has also developed different engraving geometries capable of correctly and differently transferring the different adhesives onto the substrates.

The revision process, therefore, involves different parts of the lines, and in particular:

• Engravings

• Cleaning systems to be integrated into trolleys or laminating stations

• Carriages intended for chrome replacement on smooth rollers or calender

• Carriages intended for anodising replacement on idle rollers

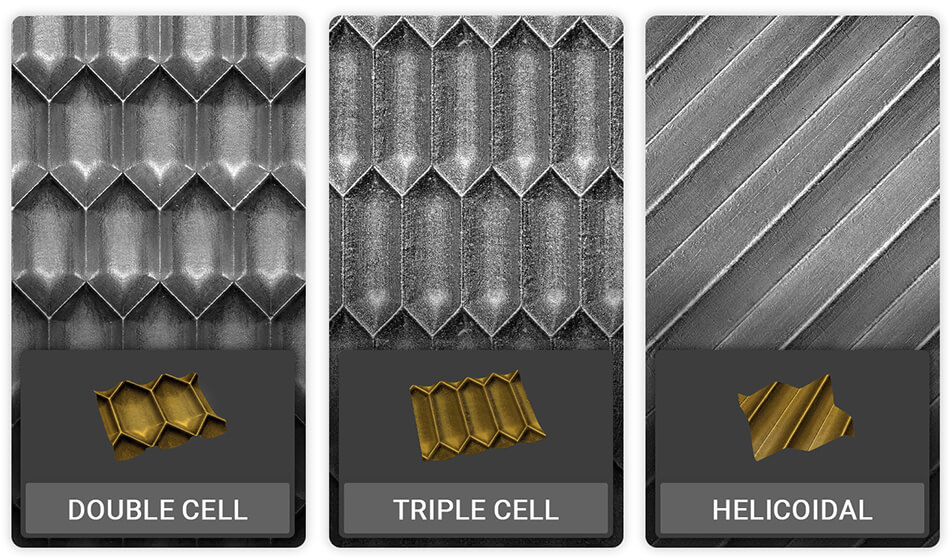

Engraving geometries

Today, solutions are available on the market that can be realised with electromechanical or chemical systems to obtain engravings on copper and chromium-plated substrates; in this case the geometries and characteristics are very limited due to the production process used and it is not always possible to find ad hoc solutions.

If we also analyse the proposals from manufacturers of mechanical engravings, although the offer in some cases could be wider, the available collections are limited and dated. This is due to the lack of investment over the years in modern technologies for the production of engraving tools.

Very often, to fill these gaps, laser engravings on ceramics have been opted for, which are poorly suited for this process due to the characteristics of the engraving system and coating. Although they reduce part wear, they compromise the stability of the product transfer.

Simec Group has invested heavily in the creation of a collection of engravings with geometries capable of changing the distribution of material on the product, allowing a reduction in the amount of material applied and increasing its release rate. This has resulted in a reduction in cleaning problems and, therefore, coating stability.

Cleaning systems

Simec Group has acquired patents for an innovative cleaning head that allows it to be easily applied on gravure and flexo carriages, or even directly on the production line. Important projects are currently underway with leading plant manufacturers to study the installation of this head on different types of lines.

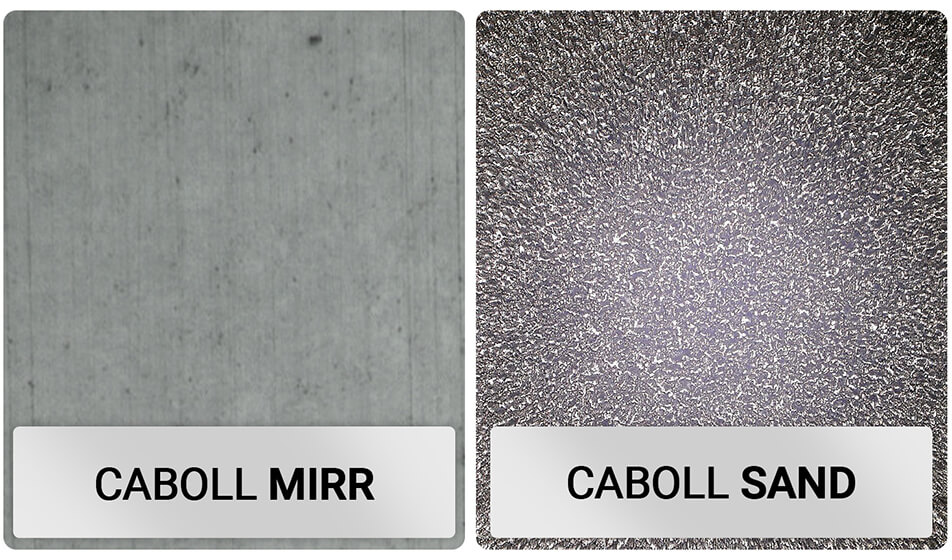

Alternate carryovers

The new product developed by Simec Group, Caboll, is having great success on both solvent and solvent less systems, replacing the rollers with traditional chrome coatings. This new product offers concrete and relevant benefits; it reduces the gap between the rollers and, thanks to the low roughness and porosity of the coating, it guarantees fast cleaning of the rollers and a much more homogeneous appearance of the transferred material even when there are significant reductions in the applied layer. The coating has a higher hardness than a galvanic coating and is therefore much less prone to damage and scoring. In addition, it guarantees greater resistance to corrosion phenomena. The new coating guarantees high resistance even in applications where it is necessary to work at high temperatures. Its resistance has been tested at temperatures of up to 300°.

Coatings for replacing anodising on idle rollers

A series of tests were conducted for the replacement of the anodising process on idle rollers used for material transfer. Problems with damage from electrostatic energy build-up, wear and tear and cleaning have always been encountered in this area. Caboll’s new coating guarantees excellent electrical conductivity, low roughness and high wear resistance.