In the demanding world of digital print for corrugated packaging, the quest for excellence drives innovation.

Head of R&D, Corrugated Post-Print,HP Industrial Print

By Semion Birger, Head of R&D, Corrugated Post-Print, HP Industrial Print

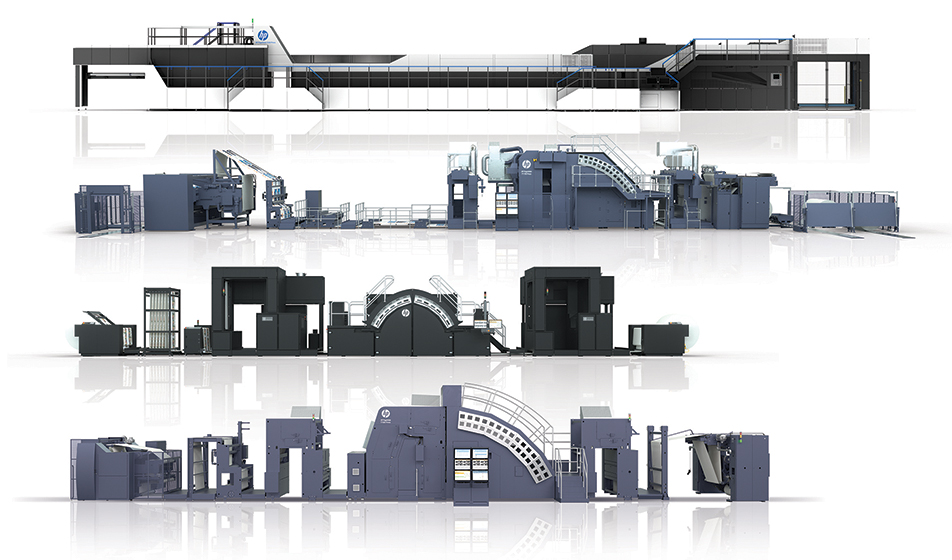

HP, a veteran in the printing industry, continues to expand its presence in the market with a wide portfolio of preprint and post-print presses. This portfolio is based on a fully integrated approach combining state-of-the-art presses, proprietary inks, and in-house manufactured printheads. This holistic approach not only sets HP apart from its competitors but also underscores the power of a synergistic system.

Why Integration Matters

Integration is key in HP’s printing technology and guarantees that each component works together seamlessly. This integrated approach allows HP to design specific innovations in ink and printhead technology that perfectly suit the mechanical printing process, leading to high print quality and press performance. Moreover, having all parts made by HP simplifies quality control, ensuring a consistent product. HP also incorporates environmental impact criteria in the design of every product and solution. Lastly, this unity means customers get straightforward support, with no need to juggle between different suppliers.

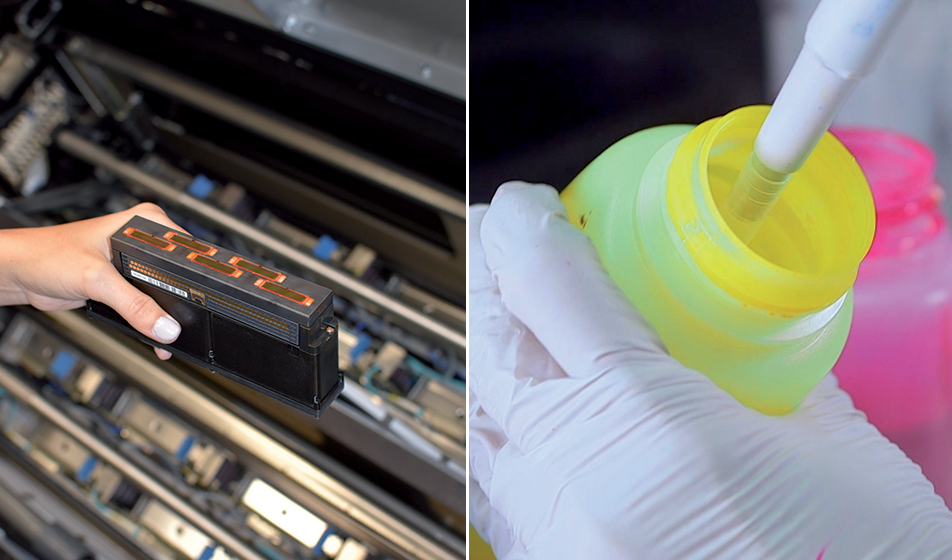

The Ink

Talented HP chemists have extensive knowledge and experience in designing a variety of inks that are used across its broad printing portfolio. Understanding the needs of the corrugated industry was the first step in the chemical formulation decision. Beyond delivering the digital promise of supply chain efficiencies and compelling marketing strategies, corrugated packaging requires inks that cater to various market applications, encompassing print quality, color, durability, and environmental impact. All this considered, HP chemists chose water as the basis for the ink. Comprised of >75% water and free from hazardous UV chemistries, HP inks are designed to address a broad range of human health and environmental considerations throughout the entire life cycle of a package. However, the reduced solid content in the ink presents a different challenge: effectively managing the jetting process of the low-viscosity liquid.

The Printheads

In this context, HP’s engineers deliberated over the most suitable technology for ejecting water-based inks in high-speed printing. The solution was straightforward – the company’s well-established Thermal Inkjet (TIJ) technology. TIJ technology involves using a series of tiny resistors that heat the ink to deposit a small ink drops onto the printing surface, resulting in high-precision print.

The low cost per nozzle makes TIJ technology cost-effective in terms of both initial investment and ongoing maintenance. Quality is achieved thanks to the high native resolution of the printheads and by leveraging redundancy capabilities which contribute to the reasonable impact of printheads on the cost of the print. TIJ technology also enables fast printing speeds, making it suitable for high-volume production and supporting fast turnaround times. With the rapid advancements in recent years, TIJ is a transformative solution that’s swiftly changing the dynamics of box production.

Synergy in Action: the HP Integrated Solution

The HP PageWide Press Portfolio exemplifies the art of integration, where the sum is truly greater than its parts. At the core of this seamless integration is a sophisticated dance between the press’s mechanics, the chemical composition of the inks, and the precision of the printheads, all orchestrated by advanced writing system algorithms. The press’s writing system algorithms are finely tuned to adapt to real-time printing conditions, ensuring that each droplet of ink is placed with unerring accuracy. This responsiveness is crucial when dealing with the fluid nature of water-based inks and the rapid-fire action of TIJ technology.

HP’s integrated solution goes beyond mere convenience; it is a strategic advantage in a highly competitive field. By taking control of the production process from start to finish, HP delivers a product that is greater than the sum of its parts. Converters who choose this integrated solution enjoy quality, reliability, and efficiency.