True water-based inks, no material waste, a low-impact and optimized processing cycle, an end-of-life that creates new value. Corrugated cardboard packaging (and not only) is sustainable only if it adopts a consistent sustainable printing technology. The HP PageWide Corrugated Solutions for converters who want to meet the criteria of the circular economy.

Consumers are concerned about the fate of an increasingly polluted and resource-depleted planet and are orienting their purchases by rewarding environmentally friendly brands. This phenomenon is well known and documented by market surveys and has a massive impact on the business of consumer goods and their packaging. Just one example, but a significant one: according to official data processed by HP, the year-on-year growth rate of sales influenced by environmental impact factors is 69%. Together with evolving legislation and policy orientations, market pressure explains the promise of big brands to limit damage (by eliminating non-recyclable or reusable packaging by 2025) and the race to find new solutions for sustainable packaging – preferably of paper and cardboard, favored as “natural” par excellence.

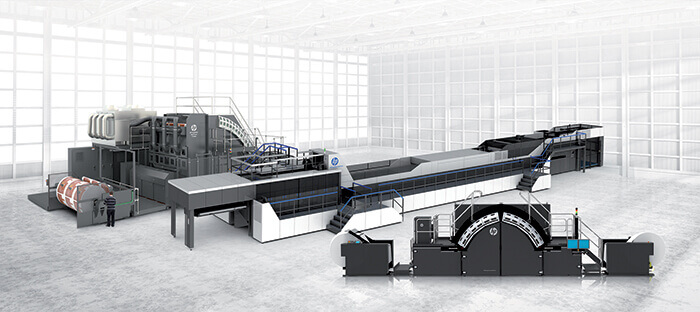

This is the context that sustains the demand for corrugated cardboard packaging, today driven by the whirlwind growth of e-commerce and the delivery service: a packaging that is far from the anonymous disposable container of its origins, having become a vehicle for image and messages, loved by marketers and the protagonist of extraordinary promotional campaigns. It is in this context that the HP PageWide corrugated solutions range of digital printing presses for packaging has developed, based on a technology and workflow that encompass all the elements necessary to guarantee the environmental and economic sustainability of packaging, producing new value for the entire supply chain.

Sustainability, a system attribute

In order to have packaging meet the requirements of the circular economy, converters need to do more than just use recycled and recyclable materials. The game also features environmentally friendly inks and adhesives, technologies that enable the printing of only what is necessary, machines that enable the waste of materials to be avoided and – last but not least – standards that enable all these performances to be measured and evaluated, wherever they are used, in accordance with the shared principles of the circular economy.

In this system made up of many elements, the machine manufacturer plays the central role of hub where ideas converge and new solutions are tested. HP PageWide corrugated solutions make the synthesis and produce state-of-the-art sustainable technology, the result of continuous investment in R&D. The manufacturer of digital printing press for packaging has worked on all levels of sustainability, to reduce the use of water and chemicals; take full advantage of the peculiarities of digital flow; minimize production waste. The result is a corrugated cardboard packaging that is part of a sustainable cycle, with the fundamental contribution of inks that are safe for human health and the environment.

Print only what you need

Print-on-demand is digital by definition: this technology was created to make short runs more economical – which today, as is well known, do not concern only print-on-demand, strong customization or for sampling and beta tests – and it is to this that it owes much of its sustainability. In fact, package allows just-in-time printing with minimal waste, and this prerogative – as witnessed by users – eliminates the need to stock up, with added benefits: reducing one’s own and customers’ stocks (and the related handling), and avoiding having to throw away “expired” stocks of printed materials or those superseded by new marketing campaigns. All this generates significant savings, also in terms of CO2 emission. Together with the elimination of plates, which digital technology does not require, and any associated washing chemicals, and including the drastic reduction in the volume of water used in the machine cleaning cycle, it’s very sustainable.

A radical choice for inks

In the HP PageWide corrugated printing system, an important role is played by the inks – a crucial element of the healthiness of the packaging and its contents, under the lens of regulatory bodies worldwide. HP R&D has focused on true water-based inks and has formulated inks for printing on PageWide corrugated solution with all the necessary safety guarantees to protect consumers and the (working and natural) environment. Free of UV-reactive chemicals, they meet international quality standards, do not produce odors and do not create end-of-life disposal problems, generating boxes that can be recycled in standard processes or composted without complications. Major international and private regulatory bodies certify this, relieving the supply chain of the (shared) responsibility of putting harmful packaging on the market. The waterbases used on PageWide are manufactured according to Good Manufacturing Practices (GMP) and certified by UL Ecologo and EuPIA; they also meet the stringent criteria of the Swiss Ordinance and Nestlé guidelines.

What about end-of-life?

If the circular economy is about the entire life cycle of a manufactured product – from sourcing and design, through production and consumption, ending with recovery to create new value – it is on this last step that consumers’ attention has long been focused. Stimulated by the media and environmental movements, it has fed a widespread culture of recycling and reuse that today is often incomplete or superficial, in the face of a truly complex subject that requires new clarifications starting from the basic terms.

Corrugated cardboard packaging made with HP PageWide corrugated solutions technology is both recyclable and compostable, and the fact that these are not general statements is due to compliance with international standards: the PTS on reduced carbon footprint printing, and the absence of additives that may affect the composting process certified by DIN Certco.