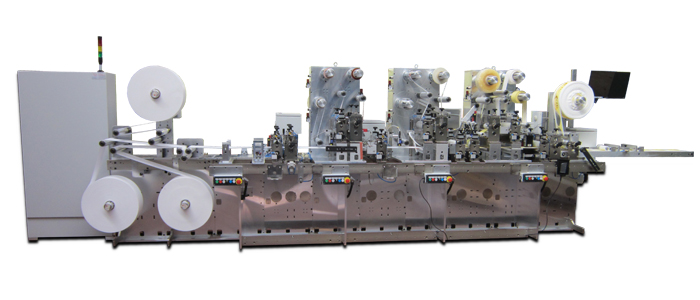

De Rossi Vittoriano Srl updates its Completa machine, characterized by high modularity and state of the art electronics. Configured to perform the printing and converting functions required, it can be updated over time.

“Completa” was born from the ability of De Rossi Vittoriano Srl to understand and serve the needs of users, starting from the one – more and more widespread among printers and converters – to have a minimum waste of start-up and production, especially for the processing of expensive materials. Completa is adaptable and modifiable according to need, so the individual units can be moved and repositioned, creating multiple configurations to perform new jobs, and more units can be added in the future, with limited costs.

Extreme modularity

Completa can accommodate a wide variety of units with different functions:

- flexo printing/coating (also front and back)

- rotary die cutting

- high performance ultrasonic welding

- longitudinal cutting or perforation

- print finishing (e.g. cold foil and multilayer printing)

- unwinding and rewinding

- lamination of different materials with control of the tension/throw of the material

- coating

- and much more.

An example of configuration

Starting from the basic model, it is possible to realize both a compact and essential machine and a real “production line” that performs, on the same platform, a great number of operations. An example? The Complete Machine shown in the picture, equipped with no less than 13 unwinders and rewinders, is configured to carry out the lamination of 3 different materials; high-performance ultrasound welding; 4 die-cutting operations; the control and ejection of non-conforming pieces; and the output on a mat.

Electronics 4.0

Thanks to the special “recipe book”, it is possible to save the settings of each job (paper “pulls”, register corrections, etc.) in order to load them later. Completa is designed to be inserted in an Industry 4.0 system and can communicate to the user information about the job in progress: type of product, average production speed, number and duration of stops, quantity produced and how much time would be left before the end of the job if it was done at the given speed.