The group will be exhibiting its new products that maximize performance and minimize usage costs at the international plastics and rubber fair (Düsseldorf 16-23 October, Hall 4 Stand C34). Spotlight on sensors and innovative control systems, inspired by the principle of integration.

BST eltromat International will be presenting the latest options for efficient quality assurance in various process steps involved in the web-processing plastics industry. Other key issues include reducing setup time, eliminating sources of error – even before machine startup, where possible – and further optimizing the user-friendliness of quality assurance systems.

BST eltromat’s extensive portfolio of innovative sensors will be a major focus of the company’s exhibition booth. «Our ultrasonic, optical, digital and wide array sensors mean we are uniquely capable of covering the wide range of requirements presented by the plastics industry when it comes to quality assurance – all from a single source», says Ingo Ellerbrock, Head of Product Management of BST eltromat.

Integration, key to efficiency

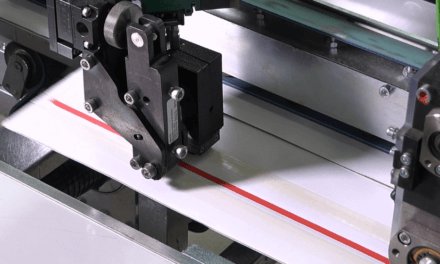

The focus in this context is on Converting 4.0, including the combination of a CLS PRO 600 digital line and contrast sensor from BST eltromat with a slitter and the the@vanced integrated platform by KAMPF Schneid- und Wickeltechnik, which will be on display in Düsseldorf.

BST eltromat will be presenting these products in Düsseldorf for its web guiding customers. Featuring the ekr CON 600 and the ekr CON 600 net, this new family consists of two innovative controllers with an extended range of features. The ekr CON 600 is also equipped with a fieldbus network connection. This means that both their setup and use are intuitive and easy for machine operators to navigate using the touch control panel.

Perfect results quickly and easily The iPQ-Center for 100% inspection will also showcase BST eltromat’s focus on simplified setup processes. The company will be demonstrating two innovative options in particular – COLOR DATAPreparation and SMART DATAPreparation – for an easyer and more simple pprocess, also in pre press.

Respond to the needs of individual customers

With its standard solutions for web guiding, register control, web monitoring and 100% inspection, BST eltromat covers a large segment of the requirements coming from the web-processing plastics industry. Depending on how BST eltromat systems are configured and networked with solutions from other manufacturers, they unlock additional options for joint customers. «This is exactly what we want to highlight in Düsseldorf, for example by showcasing our cooperation with KAMPF Schneid- und Wickeltechnik. The integration shown here is based exclusively on standard tools from BST eltromat. When customers come to us with highly specific requirements, we work with them to investigate whether developing tailor-made solutions for them is necessary or whether our standard solutions are sufficient to best support their processes. The deciding factor is that they be able to achieve their economic and environmental goals with our technology», says Ellerbrock.