Among the various technologies available, digital printing has emerged as a promising solution, offering new possibilities for efficiency and innovation.

Adi Shorer, Product and Strategy Manager, HP PageWide Industrial

In the dynamic world of packaging, corrugated converters continuously seek ways to enhance their operations and meet evolving market demands. At its core, efficiency in corrugated packaging operations means maximizing output while minimizing inputs across the board: time, materials, and human effort. It’s about striking the perfect balance between speed, quality, and resource management.

Speed Redefined

When we talk about speed in corrugated packaging printing, we’re not just referring to how fast the press runs. The real magic happens in the overall production cycle. While traditional analog presses boast impressive sheets-per-hour stats, they often fall short when it comes to setup and changeover times. Digital single-pass presses offer a compelling alternative. Consider the experience of operators using the HP PageWide C500 Press, for instance. They report setup times of just 1-3 minutes, compared to the 20-30 minutes typical of analog equipment. This dramatic reduction in preparation time can transform your production flow in several ways, making it more economically viable to handle smaller runs and more frequent job changes. Digital print can also introduce speed and efficiency gains in downstream converting. For example, laminators with roll-feeding capabilities can run faster and achieve higher throughput when running digitally printed rolls off the HP PageWide T700i Press. More so, quick turnarounds allow meeting tight deadlines and last-minute customer requests. All in all, improving your production cycles means a higher level of service to your brands.

Quality Without Compromise

In the world of retail, consistency is king. Brand recognition relies heavily on brand colors. Digital printing technology excels in this area, delivering cohesive colors from the first box to the last, ensuring that every package on the shelf presents a unified brand image. Gone are the days of laborious color matching and registration processes. With digital, color control becomes a streamlined, computer-aided process, eliminating much of the guesswork and potential for human error. This precision not only ensures customer satisfaction but also significantly reduces waste from defects and rework.

Resource Optimization

Efficiency isn’t just about time – it’s about making the most of every resource at your disposal. Digital printing shines in this area by promoting a “print what you need, when you need it” approach. On-demand printing allows for just-in-time production, minimizing warehouse space and associated costs. With minimal need for make-ready sheets, digital printing significantly reduces paper waste. In addition, digital bypasses the need for printing plates, saving on both material costs and storage space.

Furthermore, digital print reduces the amount of ink and other fluids used for preparing the press, printing, and cleaning after the print process. The innovative HP Therma Inkjet technology, for example, includes an automatic clean-up procedure for print heads to reduce water usage. In a comparison reported by one of the HP PageWide C500 customers, moving to digital allowed them to eliminate 95% of their water consumption previously used on their flexo press.

The Human Element

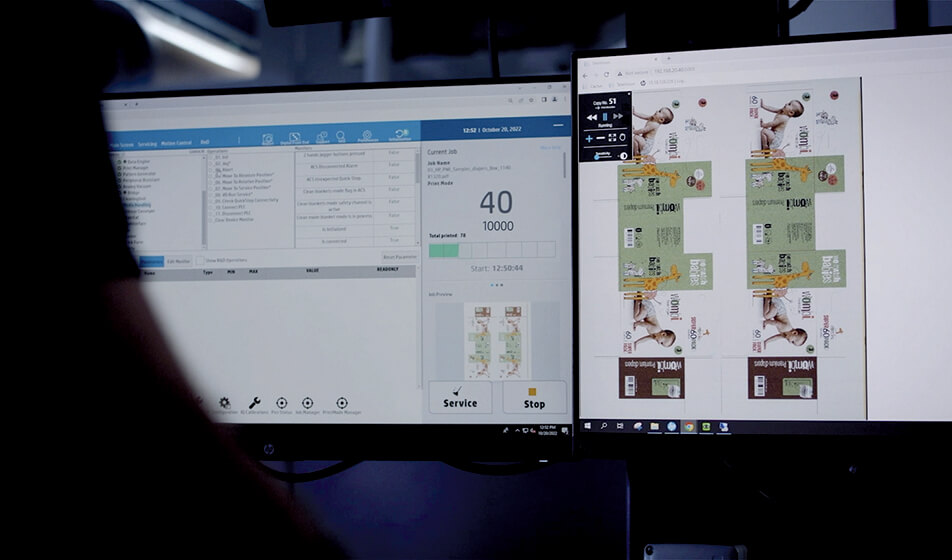

Even the most advanced technology is only as good as the people operating it. Digital printing systems often come with sophisticated support tools that empower operators to perform at their best. For instance, HP’s PrintOSx provides real-time guidance, preventive maintenance instructions, and even remote support options.

This level of support not only enhances efficiency but also boosts operator confidence and job satisfaction. It allows for a more diverse workforce, as the intuitive interfaces and guided processes make it easier for employees to transition from other roles or industries. Moreover, the shift to digital often leads to upskilling opportunities for the workforce. Operators can develop new competencies in areas like color management, workflow optimization, and digital file preparation, adding value to both their personal skill sets and the company’s capabilities.

The Bottom Line

In an industry where margins can be tight and competition fierce, the efficiency gains offered by digital printing can make all the difference. By reducing setup times, minimizing waste, ensuring consistent quality, and empowering your workforce, digital printing technology positions your business for success in ways that traditional methods simply can’t match.

As we look to the future of corrugated packaging, it’s clear that digital printing is becoming an increasingly important tool in the converter’s arsenal. By embracing this technology, businesses aren’t just keeping up with the times – they’re positioning themselves at the forefront of innovation, ready to meet the challenges and opportunities of tomorrow’s market.