At the ColorConsulting booth (Hall 6, Stand 6D19), you will have the opportunity to request live demonstrations of the solutions developed to address the daily challenges related to color reproducibility and repeatability faced by modern printers. Through dedicated video case studies, you will discover how to use the best software and tools to solve even the most complex problems related to color and ink management. The astonishing results achieved will be presented directly by the voice of our satisfied customers.

ColorConsulting offers a comprehensive set of products, which together with our collaborations with partners Alwan Color Expertise and X-rite, enable the management of the entire color workflow, from file optimization, to ink formulation, and quality control during production. Among the innovations we will present, the highlight is the new release of ColorSoftware Suite’s ColorTrack, which includes the implementation of the “Pantone v5” guide and the “Quick Compare” function. This function will allow you to quickly measure random color samples during the print run, regardless of the active job in the software at that time. It will also expand the capabilities of your spectrophotometer with all the calculation options available in the software.

But that’s not all. We will also present version 6.0 of InkWeigh, which offers improvements and new features, achieving what we call “Smart Traceability.” It will now become extremely simple to search for production batches: with just one click, you will have access to all traceability information. You can discover which jobs, leftovers, or warehouse positions contain a specific ink batch, or conversely, which batches have been used in a specific job. Furthermore, you can search for batches in the warehouse, including those in production leftovers. The most innovative feature of “Smart Traceability” is the ability to track batches used along different productions, allowing you to keep the ink on press and use it in various jobs while still keeping track of the batch, without having to return it to the warehouse between jobs.

Another interesting new development is the direct import of recipes into InkWeigh. This feature is particularly useful for the label industry, which often needs to create small quantities of ink without having to purchase print ready inks color by color. Implementing this functionality can lead to considerable cost savings, offering an unparalleled ROI.

Furthermore, we will complement our exhibition with Alwan’s software, particularly the well-established PrintStandardizer. This software enables offset and label printers to achieve all industry standards (ISO, Fogra, G7, etc.), reducing setup times, decreasing waste, and improving print repeatability and quality.

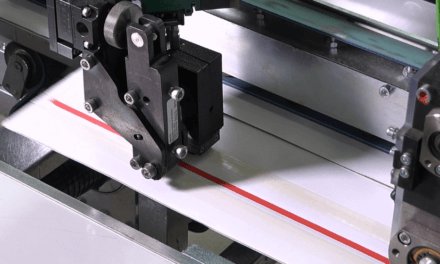

Finally, you will have the opportunity to discover the innovative HydraFix® technology, which, in combination with Alwan ColorHub software, provides a unique solution for label printers using digital or hybrid technologies. We look forward to welcoming you at our booth to experience these innovations firsthand!