More than 130 delegates met at this year’s EUROSAC Congress from 4–6 May in Verona, Italy, for a vibrant knowledge transfer and networking. Under the motto “Paper sacks: from nature to nature”, the discussions focused on recent EU packaging legislation and on various approaches for paper sack recycling and fibre recovery. The grand finale was the presentation of the industry’s most promising innovations at the EUROSAC Grand Prix Award. Saccarta won the Gold Award with its Window Valve Bag. dydry from dy-pack was honoured with the Silver Award. Performance White Barrier by Billerud and EcoLayer by Klabin convinced the jury as Bronze Award winners. The entry Next from Alier received special recognition with the Industry Special Award. Most popular among the audience was Mondi’s Protector Bag ExpandForm. It received the Public Choice Award.

The European paper sack industry is increasingly joining forces: EUROSAC welcomed five new members during the Congress. “Our industry is doing well although it is going through a complicated period,” EUROSAC president Olivier Tassel said in his opening speech, referring to the difficult economic situation and low demand on the paper sack market. “There are challenges – and there are opportunities. I am convinced that we will receive many valuable insights from today’s presentations and discussions to seize those opportunities by using the advantages of paper sacks.” Despite the challenges faced in 2022, such as broken supply chains, exploding energy costs and shortages posed by the war in Ukraine, the European paper sack industry developed on a similar level as in the previous year with a total of some 6.2 billion paper sacks. It delivered only slightly less (–2.6%) paper sacks than in 2021. The variation was mainly driven by the construction sector which has a 60% market share and recorded falling delivery figures: –7.2% in the paper sack market for cement and –4.6% in building materials. Chemical products

(–4.3%) and milk powder (–1.5%) also saw dropping deliveries. The sectors food products except milk powder (+9.1%), animal feed (+4.1%) and minerals (+1.7%) recorded gains. The downturn still affects the industry. This is reflected in –12% paper sack deliveries in the first quarter of 2023.

Progressing towards the targets of EU legislation on packaging

From the EU Green Deal through various environmental policies, to the Packaging and Packaging Waste Regulation – the audience dived deep into the latest developments of the fast-moving EU legislation affecting the paper sack sector. “In 2030, the sustainability of paper sacks will need to be proven,” explained Krassimira Kazashka from CITPA. “The paper and board packaging industry is smart, innovative and capable to face the challenges and shape a sustainable future.” Also on the agenda was an update on the industry’s recent communication and research activities, which are contributing to the fulfilment of the ambitious targets. In line with the Congress motto “from nature to nature”, a special focus was set on initiatives and companies supporting and accelerating the circular economy with industrial paper sacks. A presentation of a breakthrough waste recovery technology from the US gave inspiration to the participants on how to recover fibre and promote circularity of resources. Examples of different approaches in the EU towards the collection, selection and recycling of paper sacks were presented from France and Italy. The French model focuses on the extended producer responsibility to create the financial system for recycling. At the heart of the Italian model was the collaboration with all important stakeholders along the paper sack supply chain. Together, they initiated a circular project for the collection, separation and recycling of paper sacks from the building materials sector.

Exciting novelties at the EUROSAC Grand Prix Award 2023

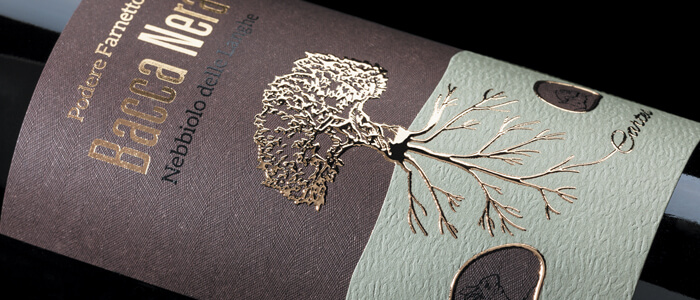

The innovative spirit among the EUROSAC member companies is high: the prestigious Grand Prix Award saw an overwhelming participation of 11 entries from six companies. The Award honours those innovations that add the most value to the industry’s customers and the environment. “It was hard to pick the winners among these very different entries. They all show that our industry advances on a high level not only towards requirements imposed by legislation but also towards market needs,” said jury president Herbert Rode. The Gold Award was presented to Saccarta for their innovation Window Valve Bag. “The solution has a high practical relevance, and holds many advantages for the end user and the environment. Added to that, it can be used for a variety of products from different segments,” explains Rode about the jury’s decision.

Grand Prix Award winners 2023

The Window Valve Bag is a logical evolution of their successful open mouth window bag. A window in the paper sack construction allows the end user to see the product inside. The sack is the sustainable alternative to traditional plastic valve sacks. According to Saccarta, it offers an 80% reduction of the environmental impact compared to plastic sacks as well as lower recycling costs. Due to its breathability, the risk of contamination is minimised. Customers also benefit from higher filling speeds, easier palletisation and improved printability.

The Silver Award went to dy-pack for the dydry pack. The packaging for planting granulates is made almost entirely from paper and can hold moisture inside while it is dry on the outside. This way, it maintains and safeguards the moisture level of the product. The sack has an excellent CO2 footprint and is designed for recycling, according to dy-pack. It can be filled on existing packaging machines and features a watertight construction.

The Bronze Award was shared by two product developments that tackle the challenge to replace fossil-based plastic with a renewable paper-based solution: Performance White Barrier from Billerud and EcoLayer from Klabin.

The coated barrier sack paper Performance White Barrier replaces slitted and perforated films used as moisture barrier in paper sacks. It can easily be transitioned in the current supply chain without changes in the production equipment. Producers benefit from a dust-free and fully recyclable sack as well as from the reduction of plastic, fossil content and CO2 emissions (30% according to an LCA from Billerud).

EcoLayer is a sustainable paper sack solution with a double barrier made by different layers of resin paper, developed for the fertiliser market. This dual protection keeps the bagged product free from moisture absorption. The resin paper is recyclable and repulpable, without generating residues during the process according to Klabin. The solution reduces the use of fossil-based plastic film and the costs of post-consumer packaging recycling processes.

Special recognition was given to Next from Alier in the form of the Industry Special Award. The company presented 100% recycled semi-extensible paper for sacks made 100% from post-consumer paper and cartons, including beverage bricks. Thus, the solution reduces waste and greenhouse gas emissions, while giving a second life to these materials. It is designed to be durable and tear-resistant, can be customised for different products, and meets the regulatory requirements for sustainable packaging solutions.

The audience’s favourite was Mondi’s Protector Bag ExpandForm. It won the Public Choice Award. This paper bag has an expandable feature to safely pack mattresses, bedding and upholstery. It replaces the current plastic packaging with a flexible and recyclable alternative. The solution is customisable and can expand to different sizes. It is made with Mondi’s kraft paper, which is responsibly sourced and renewable, and can be recycled, contributing to a circular economy. Moreover, it is suitable for printing, puncture-resistant and breathable.

More innovations from the industry

Among the other Grand Prix entries was Fabrik by Alier, which is a durable 100% recycled paper that is crafted from a unique blend of textile waste and post-consumer beverage cartons. Primarily utilised for shopping bags, the usability is being tested for other markets such as e-commerce, the fast food industry and sack paper production.

Klabin entered the EUROSAC Grand Prix also with their e-commerce and delivery solution Antiviral e-BAG. The paper packaging contains an organic-based antiviral agent with proven efficacy in inactivating and destroying viral genetic material. At the same time, it maintains the recyclability and biodegradability properties of paper.

Made from an innovative paper based on eucalyptus fibres with high mechanical resistance, Carry EukaBAG from Klabin is a sustainable paper sack for heavy products. It can be filled easily without a filling machine through the open mouth of the sack. An additional paper closes the open end and prevents leakage of the bagged product. Thanks to its handle, the sack offers good ergonomics.

With circularity for used paper bags, Mondi, together with other partners, is successfully piloting the collection and recycling of used paper sacks from the building sector. The circular model includes the participation of customers, construction companies, specialised collectors and recyclers. It is implemented in Spain and Austria and can easily be rolled out to other EU countries and industries.

The Customer-Oriented Bags Standardisation Tool (COBST) is a digital application developed by Mondi. It allows customers to standardise their portfolio according to their needs by performing feasibility tests and calculating optimal pallet layouts. The entire process is fast, simple and intuitive. The result is a less complex portfolio which saves space, time, money and is good for the environment.