Gavin Rittmeyer, VP of Sales and Marketing for Martin Automatic

Nick Coombes recently had the opportunity to sit down and catch up with Gavin Rittmeyer, VP of Sales and Marketing for Martin Automatic at the company’s headquarters in Rockford, IL. They spoke about the changes at Martin from recent investments to new market opportunities.

NC: Martin’s HQ looks different to the last time I was here. Can you tell us about some of the changes you’ve made over the past couple of years?

GR: Well, on the production floor we have continued to invest in multi-axis and automated machining centers. The mix of automated lathes, 3- and 5-axis vertical and horizontal mills along with a 5-axis gantry machine makes 12 new machining centers we’ve brought online since 2019. These investments are geared towards the new talent that we are looking to recruit and our long-standing common-sense use of technology to make us more efficient. We continue to cross train new and seasoned machinists in the different technologies that we have in the machine shop – again, a focus on keeping everyone sharp, engaged, and efficient at all levels. The new machining centers augment this process really well.

NC: You appear to have extended the assembly area – what’s in there right now?

GR: We have expanded the bays, and in particular the tall bay where we build our high-speed paperboard and wide-web non-woven machines that run 700 – 900m/min. One of the largest machines we manufacture can take up to 23 seconds to complete a splice, and the festoons for these machines require a very tall bay. We managed to enlarge the bay by repurposing storage to give us about 20% more production space – all without engaging in a costly addition to the facility.

NC: And I see there’s now a demo center too – how is that working out?

GR: We’re very proud of the new demo center area that currently features our space-saving MBS butt splicer that has 1.7 m footprint in the running direction for a 430 mm wide web. We’re also showing our LRD rewinder with another keen space-saving device for installations that short on space, and a Lemu model GTU multi-spindle finishing turret rewind. All three machines are inline and show how converters can use a jumbo roll rewind and finishing turret rewind on the same line for maximum flexibility, and all in the smallest floorspace possible. We are delighted to be working with Lemu – their multi spindle turret rewind and label converting systems, which include automatic packaging of finished rolls, are thoughtfully designed, and well made – their design philosophy and business practices closely align with ours. We supply them with butt splicers and they supply us with finishing turret rewinds when the application calls for it.

NC: It’s always fascinating looking out over your production floor – why is there such a great variety of equipment?

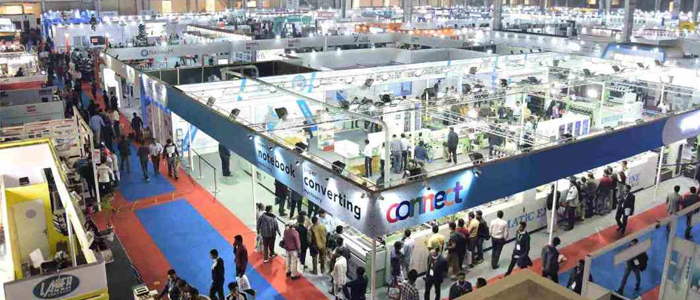

GR: It’s because we are fortunate to work with and supply so many different market sectors. Looking at the shop floor now and for the coming months, nearly every market segment that we target from building materials to lottery tickets, labels, disposable hygienic, disposable plates and cups and folding carton are all represented. The variety of colors, representing all different OEMs is interesting and tells a great story – we have learned to work with a wide cross section of converters and converter OEMs and have come to understand their different processes and the specific needs of customers in these varied markets.

NC: What is that monster out there right now?

GR: It’s a unique machine that we call our MTL 11-67-96 that has just been approved for shipment by the customer. It’s one of our largest machines by volume, consuming around 19m of floorspace in the running direction. It unwinds and splices non-stop a 2mm caliper fiberglass matt web that’s 1.7m wide and has a 2.5m diameter at speeds up to 350m/min. The process this machine feeds is used to make asphalt roofing shingles – the entire production line is well over 150m long.

NC: Martin is probably best known in the printing industry – what’s happening for you there?

GR: The digital press industry is showing a lot of promise for growth. The automation of unwinding and rewinding webs of material on digital presses or finishing lines was previously overlooked because of short run lengths, narrow web widths, and slow running speeds. However, there has been a shift in attitudes, and cost models are being re-evaluated. Most recently, Martin has been accredited by HP technicians in Tel Aviv to work with their Indigo 6000 and 8000 lines.

The principles of integrating with digital presses are similar to those of analogue presses. Martin’s automation is already in use in commercial production on various presses, such as Domino, Gallus, Kodak, and HP, producing products ranging from self-adhesive labels to toothpaste tube laminates, direct mail pieces, and paperboard products.

NC: Looking ahead, what else do you see on the horizon?

GR: We are always seeking new markets and high value-added webs to automate. Newer markets include highly engineered anode and cathode webs used in the high-volume manufacture of batteries for EVs. We are also finding success with filter media webs and specialized tube webs for food casing and C-folded webs for garbage bag production.

NC: One final question – what is that up on the roof?

GR: You’ve noticed! Our rooftop solar installation has now been online for just over a year. It’s a 1.2-megawatt system consisting of over 2800 solar panels, making it one of the largest solar installations in Northern Illinois. And it’s performing exceptionally well – we’ve seen up to a 75% saving when comparing monthly energy costs year on year. Another great example of Martin looking ahead!